SoftPLC

control logic

SoftPLC control logic for the whole saw mill

Inx-Service’s intelligent measuring and optimizing solutions cover the whole range from log yard to planer mill. All the needed control logic can be implemented with the integrated SoftPLC application by Inx-Service.

Control logic system and measuring solution are integrated seamlessly together with the whole saw mill process, because both software solutions run in the same server. Both solutions are connected to the same EtherCat-bus and use the same IO-system. This ensures a fluent communication between the control logic system and the measuring solution.

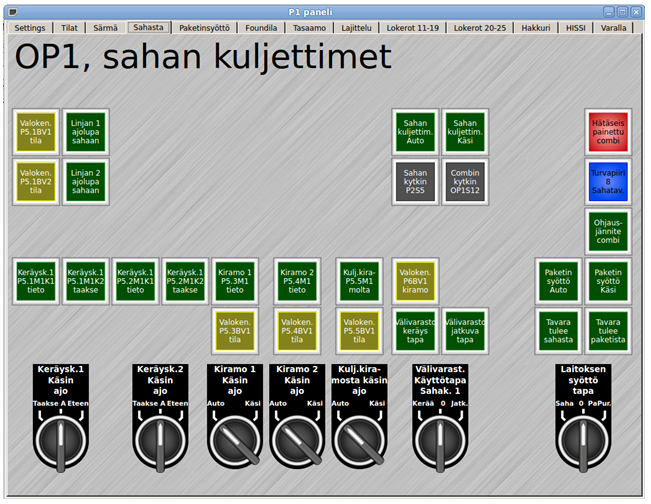

Friendly user-interface

The user-interface of logic control system is based on the use of object-tailored touchscreen, which enables easy and graphic follow-up and control of the sawing process. The user-interface functions are defined with the components integrated in the own Qt-development tool by Inx-Service. As the control logic is a fully-integrated part of the measuring solution it simplifies to do any adjustments during the whole life-cycle of the system solution.

Flexible application development

Logic control functions are defined with the graphical application development tool. This generates the application source code in C-language that is translated and complied into the software package. Further applications can be developed with all logic program languages according to the IEC 61131-3-standard.

The application development tool will be installed in the customer’s server for coming needs, e.g. this enables further investigations of the control system, localise faults in detectors and cabling as well as to modify the control logic application.