Log handling

Automation for log handling

Inx-Service’s automated system solutions measure log dimensions and grade factors and in addition to log sorting they can take care of other control inspection measurements at the saw mill, if needed.

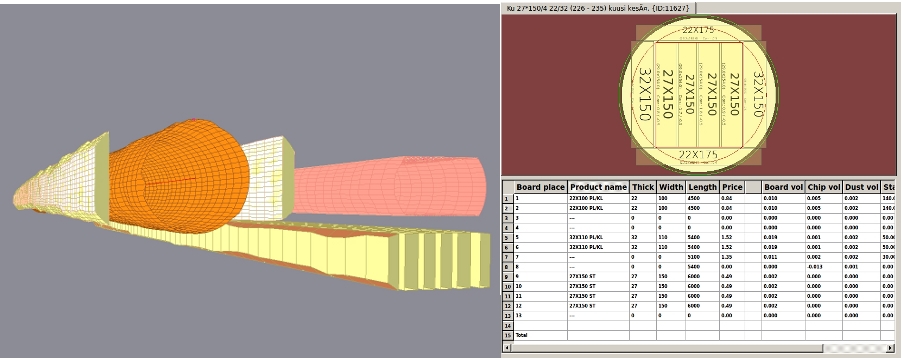

Measurement resolution in log sorting can be improved using 3D meter with the in-built measuring unit that measures the true shape of the log under the bark.

Log profiling measurement data is used to control turning and rotating the logs in the saw line and adjusting log-specific saw trims.

Log sorting and saw mill measurement system can be enhanced with a log yard inventory solution that follows warehouse situation log by log. Log sorting adds automatically the number of logs in the log class warehouse and log measuring at the saw intake decrease the number of logs from the log class, respectively.

Reporting in Inx-Service solutions is based on the large amount of measurement data stored in the database. This enables versatile and long-term reporting on different phases of production processes.

In log handling as well as in the whole saw mill all the control and supervision of machines and feeders can be implemented using SoftPLC logic control software instead of using the traditional logic control. Then all the measuring and optimizing systems may be very easily integrated with the whole control system of the saw mill.

Inx-Service´s measuring and control solutions can be also integrated with the existing logic control system (e.g. Siemens, Omron or Mitsubishi) via Ethernet with TCP/IP protocol. Then the new system takes care of all the measurement, calculation and bin control functions whereas the existing logic control system supervises and controls feeders and conveyors as well as other related equipment.