OptiGrader GS

-optimizes the heartwood sawing

OptiGrader GS optimizing system for square-sawn lumber

The OptiGrader GS (Green Split) optimizing system maximizes the end product profit obtained from the square-sawn lumber and determines the optimum sawing method.

The OptiGrader GS measures the lumber form, knots and other defects from four directions. The system combines the grade factors with the pricing of end products and chips. Following this, it computes the optimum sawing method for the lumber, so as to maximize the amount of end products with the highest value.

For example, the system can decide which part of the square-sawn lumber is suitable for floor boards and which for door frames. With end products as the basis it also defines the sawing orientation of the lumber.

This maximizes the product value which can increase by as much as 10 percent, compared to conventional sawing. The end products are determined along with their volumes prior to drying and remanufacturing, which boosts the efficiency of the final production phases.

An award-winning machine vision application

The OptiGrader GS examines the square-sawn lumber from four directions. A matrix camera is used to measure the dimensions (1,000 images per second) and a true-color line-scan camera is used to measure the grade properties (4,000 images per second). The system identifies the grade factors with the aid of a machine vision application based on neurocomputing that simulates human brain activity. The system can be taught to identify new defect types with the aid of concrete images.

The application has been awarded the EC Vision Prize for the best cognitive machine vision system, which reflects Inx-Services’ leadership in the development of self-learning measuring systems.

The image processing technology used by the system is patented.

Office electronics is no match for this line of work

The system electronics was designed for industrial conditions and the equipment processing power was dimensioned for machine vision applications that require massive computing power. This ensures the equipment reliability and the measurement accuracy, which cannot be achieved by computers that are designed for office purposes.

The user interface complies with the specific needs of wood processing, providing a clear view of the production in progress. The user sees the measurement results of all pieces being p

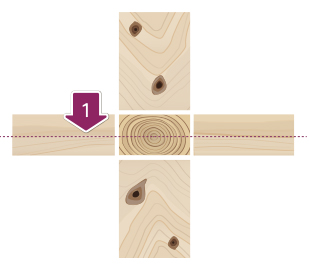

Sawing situation 1

The OptiGrader GS identifies the highest quality pieces from the square-sawn lumber and computes the most profitable sawing method for them. In this case, horizontal stripping is enabled by knot-free edges, with valuable floor planks produced as the end-product, for example.

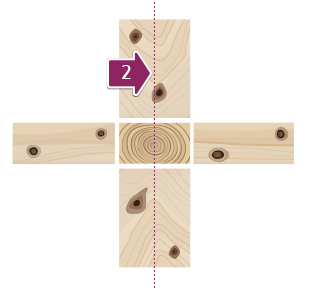

Sawing situation 2

Since the edges are knotty, the OptiGrader GS selects a vertical sawing line as the most suitable sawing method for this situation, with frame timber produced as the end-product, for example.