OptiLog

-saw pattern optimizer

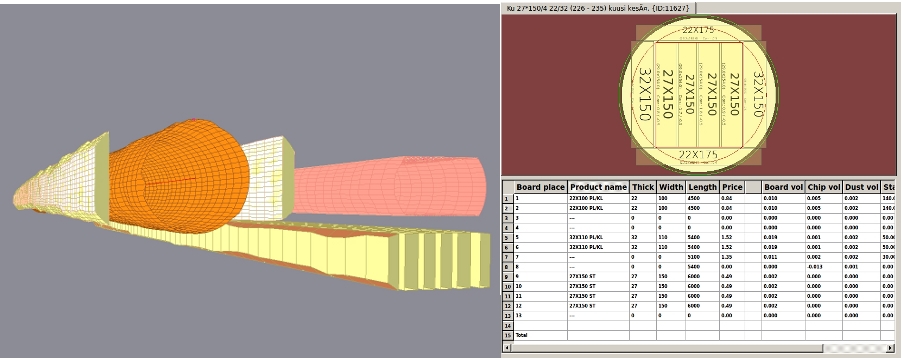

The OptiLog saw pattern simulation and optimization system

Establishing the correct saw pattern is a complex problem. It is a combination of numerous factors, such as the log form, quality and costs, as well as the chip and lumber price range.

The OptiLog software is used to manage the effects of these factors. It computes the most profitable saw patterns for the logs and enables saw-pattern-based sorting. Provided that the saw patterns can be controlled in real time, OptiLog can optimize the saw pattern for each individual log.

Both methods increase the yield significantly and boost the profit, even by several million euros per annum.

Simulation-based virtual sawing

Most importantly, OptiLog can also simulate the sawing of stored logs, thus ensuring the most profitable end result in advance.

OptiLog may be used for the virtual sawing of a log batch based on various saw patterns, for example when designing the saw patterns for new products based on existing log categories, or searching the existing saw patterns for the most appropriate sawing methods for new log categories. This means that the system is able to establish the optimum saw patterns for all situations thus ensuring profitable sawing in advance.

OptiLog can also be used retroactively to simulate the re-sawing of previously sawn log batches using various saw patterns, provided that the log handling measurement data is accessible for the system.

Utilizing all information

In addition to the ScanLog 3D log profiling system, OptiLog integrates smoothly with 2D and 3D scanners produced by other manufacturers, and exploits their results in computing. In cases where an X-ray scanner is in use, such as the ScanLog 1X, OptiLog also considers the log quality and the end product grade factors during optimization. OptiLog continually updates its models with the aid of the raw materials used and the production achieved, provided that the system can be interfaced with the sawmill’s ERP system.

OptiLog operates in the Windows environment. System operation is illustrative and provides clear reports on the calculations performed and the final sawing results obtained. OptiLog integrates seamlessly with the sawmill’s information systems and measuring equipment.