EdCon

-controls the outcome quality of the edging

The EdCon edging inspector

EdCon measures the piece dimensions and wane after edging using triangulation. The measurement technology is based on line lasers and a matrix camera that takes 1,000 images per second.

EdCon works best together with an edging optimizer, such as the OptiGrader Edger or the OptiEdger. EdCon monitors the piece dimensions and wane profiles and issues an alarm if the objectives received from the edging optimizer are not fulfilled.

This is most probably due to a malfunction in the edger, pressure rollers, blades or conveyors. Without EdCon, erroneous sawing could go on for weeks before the problem is detected, by which time the monetary losses could have increased to a significant degree. The basic principle in all processing is to immediately check that the dimensions are correct.

Office electronics is no match for this line of work

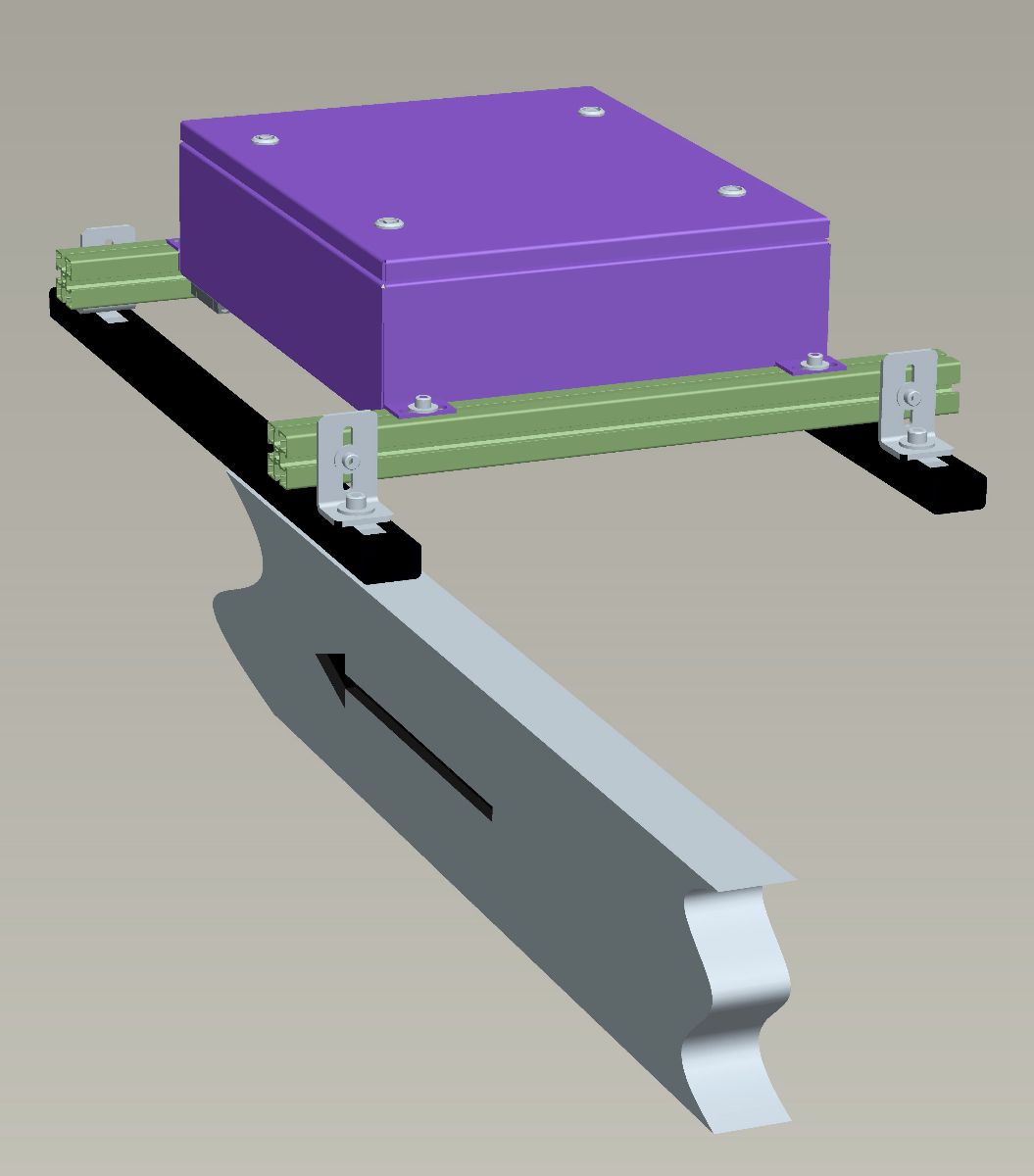

The system electronics was designed for industrial conditions and the equipment processing power was dimensioned for machine vision applications that require massive computing power. This ensures the equipment’s reliability and the measurement accuracy, which cannot be achieved by computers designed for office purposes.

The user interface complies with the specific needs of wood processing, providing a clear view of the production in progress. The user sees the measurement results of all pieces being processed in a clear graphic form and receives an immediate alarm of all deviations in the production process.